Managing portfolios is a skill that requires an organized approach to the various projects and initiatives that your organization undertakes. Management of multiple projects can be complex and requires constant monitoring and tracking. Fortunately, portfolio management tools come equipped with powerful reporting capabilities. Portfolio management is a great way to maximize each project’s potential impact. Portfolio managers who are skilled in managing portfolios know when to say no to projects that do not add value.

Determining the scope and work of portfolio management is an essential component. In other words, defining the scope of work allows for proper resource allocation and an effective plan of action. Portfolio management is also a good way to communicate effectively with colleagues and leadership. You can ensure that your projects are on track by keeping track of their progress.

A portfolio is comprised of several programs, projects, and assets. It is typically managed at the organizational level, and may include processes, procedures, or other projects. Portfolios that are well managed have a central management system. This allows for more efficient execution of the projects.

Allocating the right proportion of programs to projects is an important part of portfolio management. This ratio can be a function of project size, organization, or appetite for risk. Some projects can be more expensive than others. The portfolio should reflect this. Portfolios may contain many different projects. It is important to ensure that resources are properly allocated.

A portfolio may contain several projects that are similar, but the portfolio has a higher priority. One portfolio may contain several projects that have the same goal or it could be a random collection with different priorities. A portfolio can be a powerful tool to identify the most valuable projects for your company. A project portfolio management tool can help you if your organization embarks on an innovative new venture or if you are trying for a new job.

You may need to have project portfolio management skills in order to be hired into a project management job. Portfolio managers with the most experience are able see the whole picture and to understand the relationships between projects. A portfolio management strategy that is successful should also include high-level macromanagement. This involves monitoring workflow, evaluating portfolio performance, and identifying any anomalies. You may also find an automated schedule to show how many resources are available to support the different projects in your company's backlog.

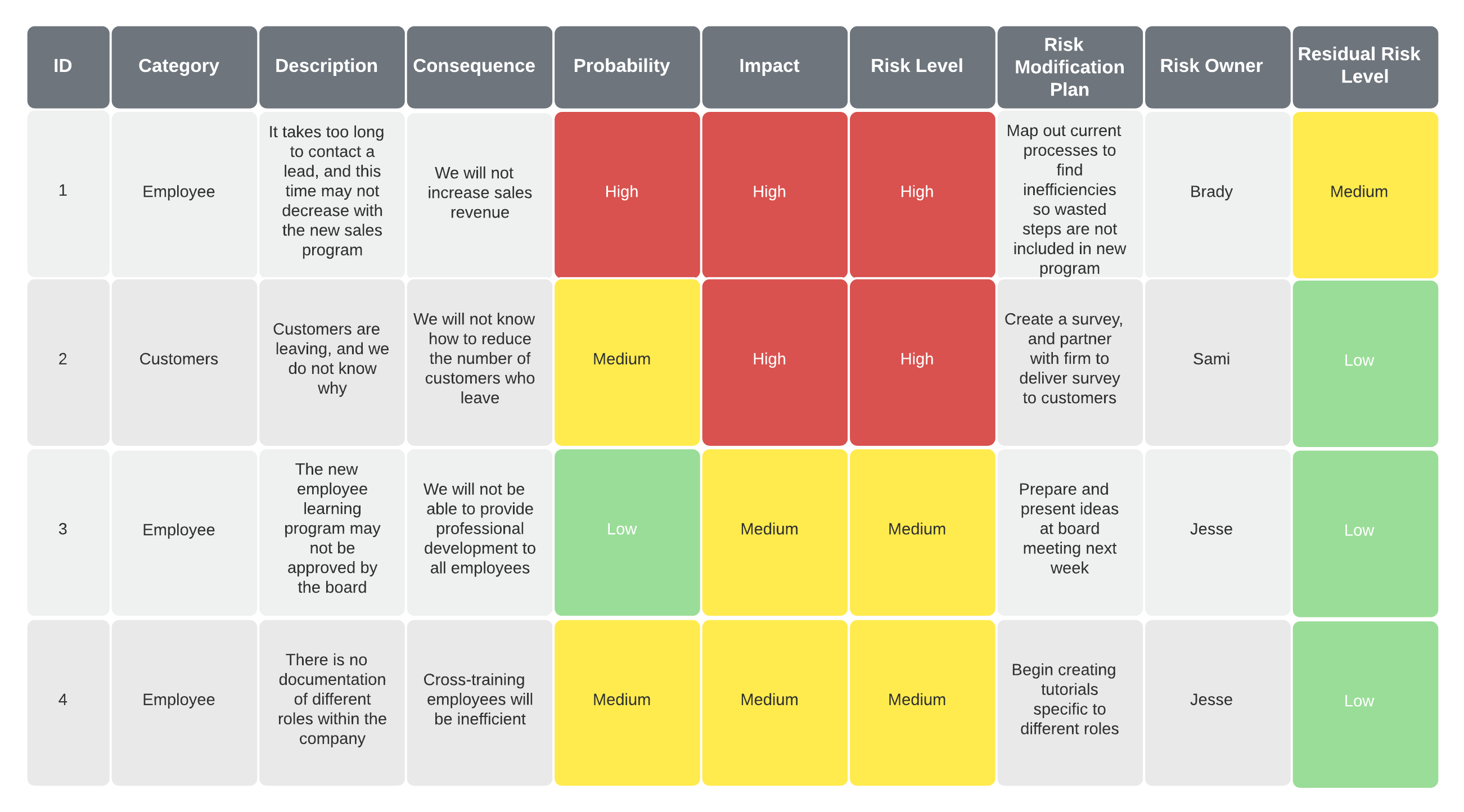

Portfolio management is an important topic. It's crucial to understand how to manage it. Portfolio management is a central management system that helps your organization achieve its strategic goals. A portfolio helps you stay organized in today's competitive world. It's a smart move to identify the largest achievements, most important projects and most dangerous risks in your organization to ensure that your investments are well-suited for the organization.

FAQ

What is the difference between TQM and Six Sigma?

The main difference in these two quality management tools lies in the fact that six sigma is focused on eliminating defects and total quality management (TQM), emphasizes improving processes and reducing costs.

Six Sigma stands for continuous improvement. This approach emphasizes eliminating defects through statistical methods like control charts, Pareto analysis, and p-charts.

This method has the goal to reduce variation of product output. This is achieved by identifying and addressing the root causes of problems.

Total quality management involves measuring and monitoring all aspects of the organization. Training employees is also part of total quality management.

It is used to increase productivity.

What does "project management" mean?

That is the management of all activities associated with a project.

This includes defining the scope, identifying the requirements and preparing the budget. We also organize the project team, schedule the work, monitor progress, evaluate results, and close the project.

What is Kaizen?

Kaizen is a Japanese term for "continuous improvement." It encourages employees constantly to look for ways that they can improve their work environment.

Kaizen is based on the belief that every person should be able to do his or her job well.

Statistics

- This field is expected to grow about 7% by 2028, a bit faster than the national average for job growth. (wgu.edu)

- 100% of the courses are offered online, and no campus visits are required — a big time-saver for you. (online.uc.edu)

- Our program is 100% engineered for your success. (online.uc.edu)

- The BLS says that financial services jobs like banking are expected to grow 4% by 2030, about as fast as the national average. (wgu.edu)

- Your choice in Step 5 may very likely be the same or similar to the alternative you placed at the top of your list at the end of Step 4. (umassd.edu)

External Links

How To

How is Lean Manufacturing done?

Lean Manufacturing uses structured methods to reduce waste, increase efficiency and reduce waste. They were developed in Japan by Toyota Motor Corporation (in the 1980s). It was designed to produce high-quality products at lower prices while maintaining their quality. Lean manufacturing seeks to eliminate unnecessary steps and activities in the production process. It is made up of five elements: continuous improvement, continuous improvement, just in-time, continuous change, and 5S. Pull systems allow customers to get exactly what they want without having to do extra work. Continuous improvement is constantly improving upon existing processes. Just-intime refers the time components and materials arrive at the exact place where they are needed. Kaizen refers to continuous improvement. It is achieved through small changes that are made continuously. Finally, 5S stands for sort, set in order, shine, standardize, and sustain. These five elements can be combined to achieve the best possible results.

The Lean Production System

Six key concepts underlie the lean production system.

-

Flow is about moving material and information as near as customers can.

-

Value stream mapping: This is a way to break down each stage into separate tasks and create a flowchart for the entire process.

-

Five S’s - Sorted, In Order. Shine. Standardize. And Sustain.

-

Kanban – visual signals like colored tape, stickers or other visual cues are used to keep track inventory.

-

Theory of constraints: identify bottlenecks in your process and eliminate them using lean tools, such as kanban board.

-

Just-in Time - Send components and material directly to the point-of-use;

-

Continuous improvement: Make incremental improvements to the process instead of overhauling it completely.